Mi sitio web

Si buscas

hosting web,

dominios web,

correos empresariales o

crear páginas web gratis,

ingresa a

PaginaMX

Por otro lado, si buscas crear códigos qr online ingresa al Creador de Códigos QR más potente que existe

Silver Nanowires

26 Nov 16 - 05:09

Making Use Of The High Conductivity Of Silver Nanowires

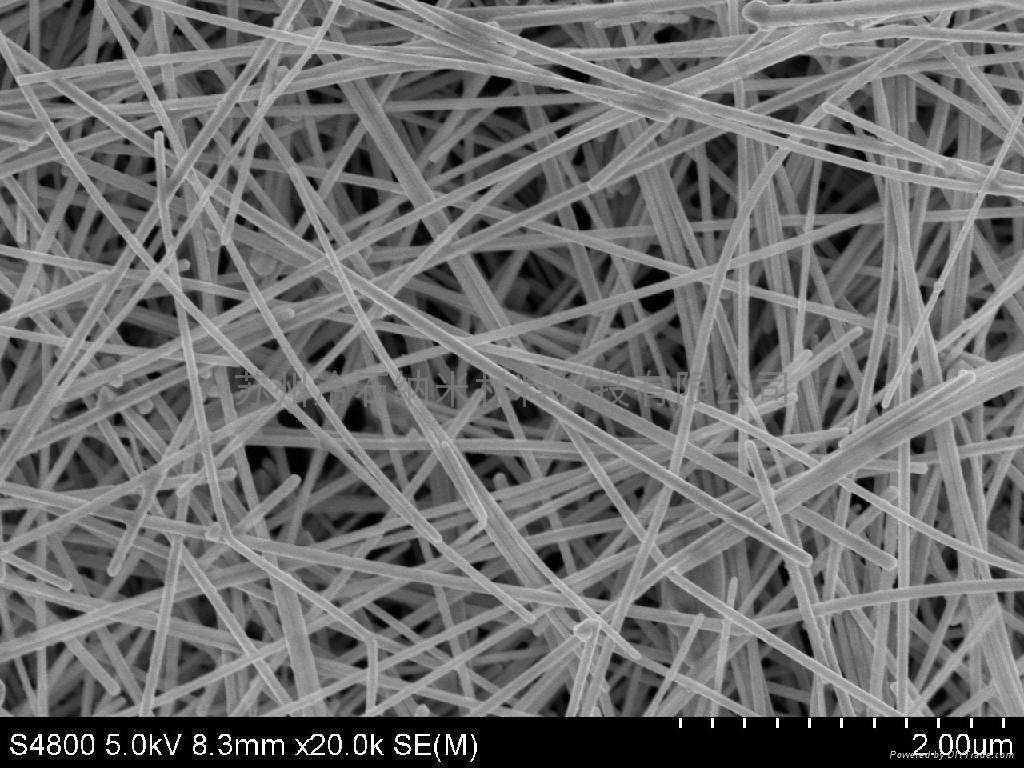

Silver nanowires have been attracting more and more attention because of their intriguing electrical, thermal, and optical properties. Silver has the highest electrical conductivity among all the metals, by virtue of which Silver nanowires are considered as very promising candidates in flexible electronics. An example is that in tablets, Smartphones, and wearable, silver nanowire film-based transparent conductors can create thinner, lighter, and stronger touch-screens. Silver nanowire has a higher transmission that also enhances battery-life-per charge and creates brighter displays.

This is because silver nanowire-based products do not impede light as greatly as traditional materials. As more product designers become aware of its touch displays, we'll be seeing an extensive array of innovative new products. Production of silver nanowires, are of great significance because it a most promising candidates to be used as conductive fillers of high-performance adhesives and as catalyst.

Production of Silver Nanowires

Silver nanowires having both transparency and conductivity are produced in an aqueous solvent at a temperature equal to or below the boiling point of the solvent, and an aqueous dispersion containing the silver nanowires, the dispersion being excellent in storage stability after coating and dispersion stability. For example, silver nanowires produced is through immersing a glass substrate on which cupper fine particles are formed by an electric deposition into an aqueous solution of silver nitrate overnight.

There are various methods on how silver nanowires are produced. The “rapid synthesis method”, “soft-solution method”, Template method and Vacuum filtration are among those. To produce an aqueous dispersion of metallic nanowires, silver nanowire-polyol dispersion is obtained through a polyol method and is then subjected to centrifugal separation and subsequent solvent replacement. Silver nanowires are synthesized using an aqueous solvent which utilizes ammonia silver in an autoclave at 120° C. for 8 hours.

Silver nanowire-based products | Image Resource : img.diytrade.com

Uses And Applications Of Silver-Based nanowires

Silver nanowires have potential applications on transparent conducting film and electrode of electrochemical capacitor due to its excellent conductivity. Transparent conducting film (G-film) was prepared by coating silver nanowires on glass substrate using Meyer rod method, which exhibited better performance than carbon nanotube and graphene. There are unlimited applications for nanowires developed with silver. But the most frequent among them are:

Optical

Solar (thin film, crystalline silicon)

LCDs

Sensors

Anti-microbial

Bandages

FilmsAir & water purification

Sterile equipment

Food preservation

Clothing

For many types of applications from OLED lighting to flexible displays, silver nanowires offer many proven benefits over ITO and competing technologies based on superior optics, weight, conductivity, flexibility and cost. The key manufacturing values of Silver nanowires are its clear production advantages versus traditional materials used in those three major product areas. The material also trumps legacy conductor materials in end-product performance.

Finally, the production of these nanowires, is a clean, automated process with low labour costs and fairly limited space requirements. Production can be quickly scaled to meet demand from giant CE product OEMs. Manufacturing with silver nanowire-based technology doesn't have a downside. Its advantages are numerous. The material is cost-effectively accelerating the transition to products we used to only imagine.

Tu Sitio Web Gratis

© 2025 Mi sitio web216336

Add a comment